Mochini o entsoeng hantle oa ho kuta le ho tšoaea oa High Speed Angle Steel Punching

Ka lebaka la tsebo ea rona e ikhethang le tlhokomelo ea litšebeletso, k'hamphani ea rona e hapile boemo bo botle har'a bareki lefatšeng ka bophara bakeng sa Mochini oa ho Beola le ho Tšoaea oa Tšepe o Potlakileng ka Lebelo le Phahameng, Khamphani ea rona e amohela metsoalle e tsoang lefats'eng lohle ka mofuthu ho ea, ho batlisisa le ho buisana ka khoebo.

Ka lebaka la tsebo ea rona e ikhethang le tlhokomelo ea litšebeletso, khoebo ea rona e hapile boemo bo botle har'a bareki lefatšeng ka bophara bakeng saHo Otla ka Tšepe ea Angle ea Chaena le ho Otla ka Hole, Ha re na ho hlahisa tataiso ea tekheniki ea litsebi tse tsoang hae le linaheng tse ling feela ka ho tsoelang pele, empa hape re tla nts'etsapele lihlahisoa tse ncha le tse tsoetseng pele khafetsa ho fihlela litlhoko tsa bareki ba rona lefatšeng ka bophara ka mokhoa o khotsofatsang.

Lintlha tsa Sehlahisoa

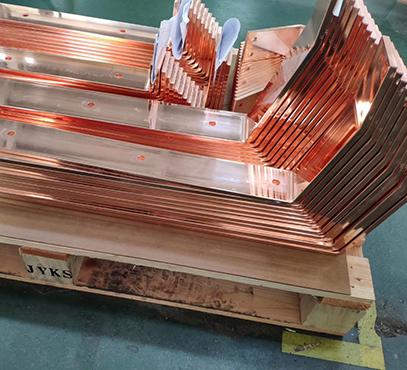

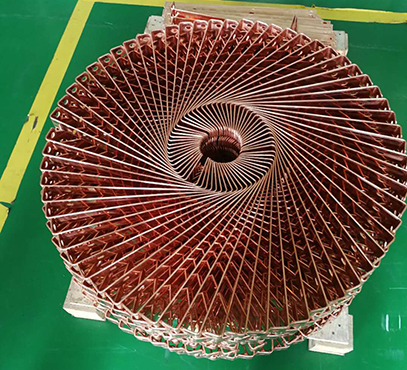

Letoto la GJCNC-BB le etselitsoe ho koba sekotwana sa mosebetsi sa busbar ka katleho le ka nepo

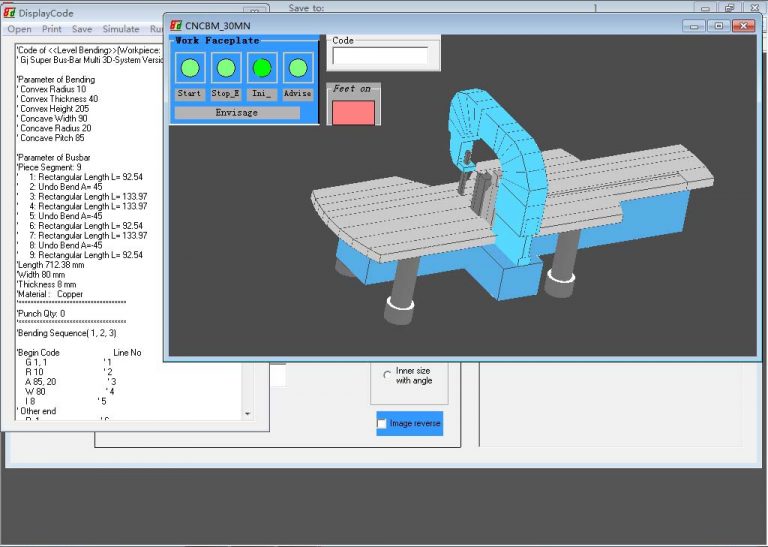

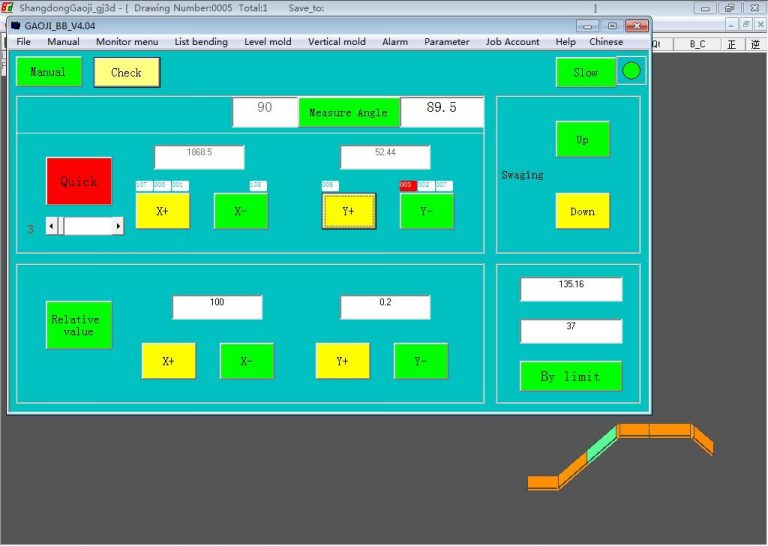

CNC Busbar Bender ke sesebelisoa se khethehileng sa ho sebetsana le ho kobeha ha busbar se laoloang ke khomphutha, Ka ho hokahanya X-axis le Y-axis, ho fepa ka letsoho, mochini o ka qeta mefuta e fapaneng ea liketso tsa ho kobeha joalo ka ho kobeha ka boemo, ho kobeha ka ho otloloha ka khetho ea li-dies tse fapaneng. Mochini o ka tsamaisana le software ea GJ3D, e ka balang bolelele ba katoloso ea ho kobeha ka nepo. Software e ka fumana ka bo eona tatellano ea ho kobeha bakeng sa mosebetsi o hlokang ho kobeha ka makhetlo a 'maloa' me othomathike oa lenaneo oa phethahala.

Sebapali se ka Sehloohong

Likarolo tsa GJCNC-BB-30-2.0

Mochini ona o amohela sebopeho se ikhethang sa ho kobeha sa mofuta o koetsoeng, o na le thepa ea boleng bo holimo ea ho kobeha ha mofuta o koetsoeng, 'me o boetse o na le boiketlo ba ho kobeha ha mofuta o bulehileng.

Yuniti e Kobehileng (Y-axis) e na le mosebetsi oa puseletso ea liphoso tsa sekhutlo, ho nepahala ha eona ha ho kobeha ho ka fihlela tloaelo e phahameng ea ts'ebetso. ± 01°.

Ha e kobehile ka ho otloloha, mochini o na le mosebetsi oa ho tiisa le ho lokolla ka bohona, katleho ea ts'ebetso e ntlafala haholo ha e bapisoa le ho tiisa le ho lokolla ka letsoho.

Software ea Lenaneo la GJ3D

E le ho etsa dikhoutu tsa othomathiki, ho be bonolo le ho sebetsa ha bonolo, re rala le ho ntshetsa pele software e ikgethang ya moralo ya GJ3D. Software ena e ka bala letsatsi le leng le le leng ka boiketsetso tshebetsong yohle ya busbar, kahoo e kgona ho qoba tshenyo ya thepa e bakwang ke phoso ya ho ngola dikhoutu ka letsoho; mme ha khamphani ya pele e sebedisa theknoloji ya 3D indastering ya ho sebetsana le busbar, software e ka bontsha tshebetso yohle ka mohlala wa 3D o hlakileng le o thusang ho feta leha e le neng pele.

Haeba o hloka ho fetola tlhahisoleseding ea ho seta sesebelisoa kapa liparamente tsa motheo tsa die. U ka boela ua kenya letsatsi ka yuniti ena.

Skrine se thetsoang

Sebopeho sa khomphutha sa motho, tshebetso e bonolo mme e ka bontsha boemo ba tshebetso ya lenaneo ka nako ya sebele, skrine se ka bontsha tlhahisoleseding ya alamo ya mochini; e ka beha diparamitha tsa motheo tsa die le ho laola tshebetso ya mochini.

Sistimi ea Ts'ebetso e Potlakileng

Phetiso ea screw ea bolo e nepahetseng haholo, e hokahanngoa le tataiso e otlolohileng e nepahetseng haholo, ho nepahala ho phahameng, e sebetsa kapele, e nka nako e telele ea ts'ebeletso 'me ha ho lerata.

Mosebetsi

Ka lebaka la tsebo ea rona e ikhethang le tlhokomelo ea litšebeletso, k'hamphani ea rona e hapile boemo bo botle har'a bareki lefatšeng ka bophara bakeng sa Mochini oa ho Beola le ho Tšoaea oa Tšepe o Potlakileng ka Lebelo le Phahameng, Khamphani ea rona e amohela metsoalle e tsoang lefats'eng lohle ka mofuthu ho ea, ho batlisisa le ho buisana ka khoebo.

E entsoe hantleHo Otla ka Tšepe ea Angle ea Chaena le ho Otla ka Hole, Ha re na ho hlahisa tataiso ea tekheniki ea litsebi tse tsoang hae le linaheng tse ling feela ka ho tsoelang pele, empa hape re tla nts'etsapele lihlahisoa tse ncha le tse tsoetseng pele khafetsa ho fihlela litlhoko tsa bareki ba rona lefatšeng ka bophara ka mokhoa o khotsofatsang.

Li-parameter tsa Tekheniki

| Boima bohle (kg) | 2300 | Tekanyo (mm) | 6000*3500*1600 |

| Khatello e Phahameng ea Mokelikeli (Mpa) | 31.5 | Matla a ka Sehloohong (kw) | 6 |

| Matla a ho Hlahisa (kn) | 350 | Setofo se seholo sa silindara se kobehileng (mm) | 250 |

| Boholo ba Thepa e Kholo (Ho Koba ho Emeng) | 200*12 mm | Boholo ba Thepa e Kholo (Ho Koba ka Tsela e Holimo) | 120*12 mm |

| Lebelo le phahameng la hlooho e kobehang (m/min) | 5 (Mokhoa o potlakileng)/1.25 (Mokhoa o liehang) | Angle e Khomarelang e Kholo (tekanyo) | 90 |

| Lebelo le phahameng la thepa e ka thoko (m/min) | 15 | Setopo sa thepa se ka thoko (X Axis) | 2000 |

| Ho Koba ka ho Sebetsa (tekanyo) | Puseletso ea koloi <± 0.5Puseletso ea letsoho <±0.2 | Bophara ba Min U bo Kobehileng (mm) | 40 (Hlokomela: ka kopo buisana le khamphani ea rona ha u hloka mofuta o monyane) |