CNC Busbar servo kobang mochini GJCNC-BB-S

Lintlha tsa Sehlahisoa

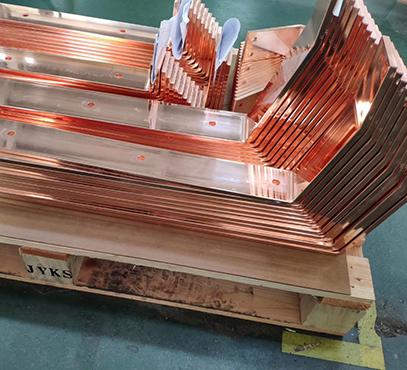

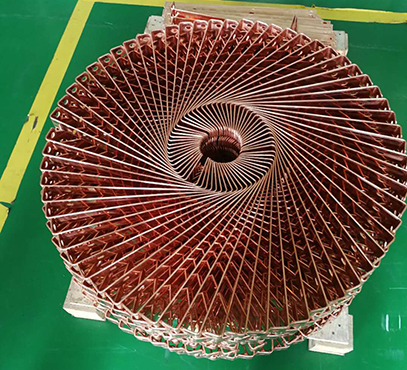

GJCNC-BB Series e etselitsoe ho koba mosebetsi oa libese hantle le ka nepo

CNC Busbar Bender ke lisebelisoa tse khethehileng tsa ho kobeha tsa libese tse laoloang ke komporo, Ka khokahano ea X-axis le Y-axis, ho fepa ka letsoho, mochini o ka qeta mefuta e fapaneng ea liketso tsa ho kobeha joalo ka ho kobeha ha maemo, ho kobeha ka kotloloho ka khetho ea mefuta e fapaneng ea lefu.Mochine o ka lumellana le software ea GJ3D, e ka khonang ho bala ka nepo bolelele ba ho kobeha.Software ka ka tsela e iketsang fumana tatellano kobeha bakeng sa workpiece e hlokang ka makhetlo a 'maloa ho kobeha le automation mananeo a hlokomela.

Sebopeho se ka Sehloohong

Likarolo tsa GJCNC-BB-30-2.0

Mochini ona o nka sebopeho se ikhethileng sa mofuta o koetsoeng, o na le thepa ea pele ea mofuta o koetsoeng, hape o na le boiketlo ba mofuta o bulehileng oa ho kobeha.

Bend Unit(Y-axis) e na le ts'ebetso ea puseletso ea phoso ea angle, ho nepahala ha eona ho ka kopana le tloaelo e phahameng ea ts'ebetso.±01°.

Ha o kobeha o otlolohileng, mochini o na le ts'ebetso ea ho koala le ho lokolla, ts'ebetso ea ts'ebetso e ntlafatsoa haholo ha e bapisoa le ho koala le ho lokolla ka letsoho.

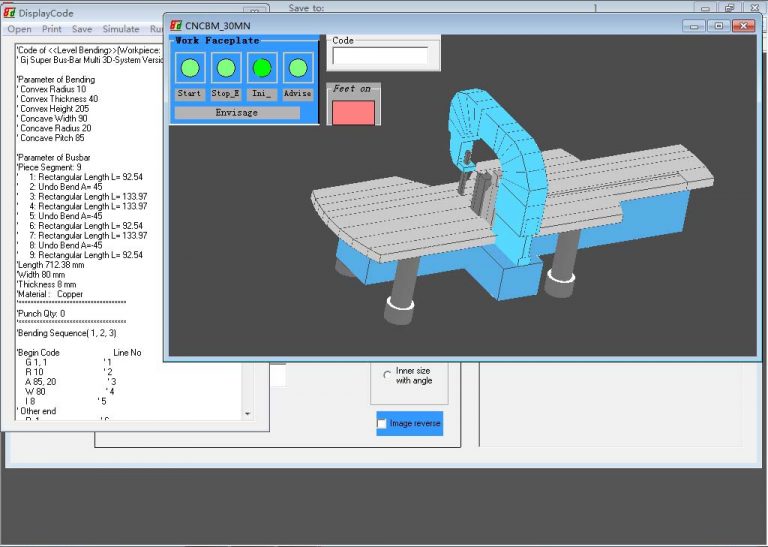

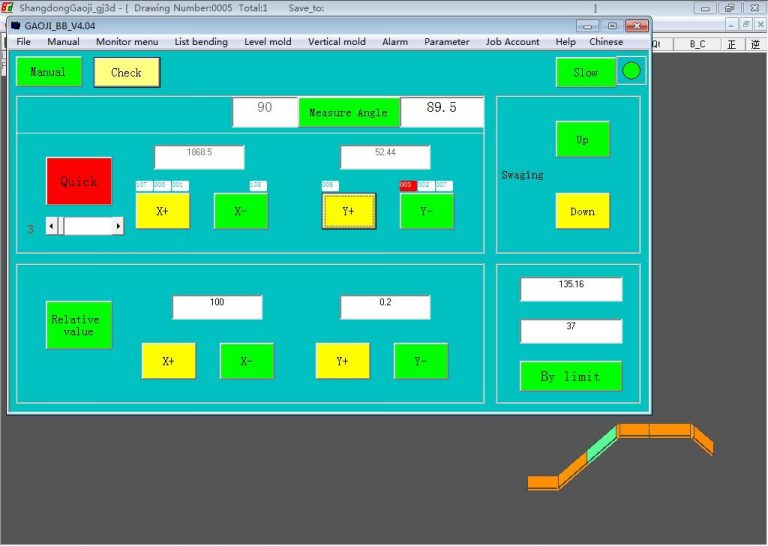

Software ea GJ3D Programming

E le hore re tsebe ho kenya likh'outu tsa koloi, ho sebetsa ka mokhoa o bonolo le o bonolo, re rala le ho nts'etsapele software ea moralo e thusang e khethehileng ea GJ3D.Software ena e khona ho bala letsatsi le leng le le leng ka har'a ts'ebetso eohle ea busbar, kahoo e khona ho qoba litšila tse bakoang ke phoso ea ho ngola ka letsoho;'me ha k'hamphani ea pele e sebelisa theknoloji ea 3D indastering ea ho lokisa libese, software e ka bonts'a ts'ebetso eohle ka mofuta oa 3D o hlakileng le o thusang ho feta pele.

Haeba o hloka ho fetola lintlha tsa ho seta lisebelisoa kapa li-parameter tsa motheo tsa die.U ka boela ua kenya letsatsi ka yuniti ena.

Sistimi ea Ts'ebetso ea Lebelo le Phahameng

Phetisetso e phahameng e nepahetseng ea bolo, e hokahaneng le tataiso e otlolohileng e phahameng, ho nepahala ho phahameng, ho sebetsa ka potlako, nako e telele ea ts'ebeletso ebile ha ho lerata.

Tekheniki Parameters

| Kakaretso ea Boima (kg) | 2300 | Boholo (mm) | 6000*3500*1600 |

| Khatello e Phahameng ea Mekelikeli (Mpa) | 31.5 | Matla a Maholo (kw) | 6 |

| Output Force (kn) | 350 | Max Stoke oa moqomo o kobehang (mm) | 250 |

| Boholo ba Boitsebiso (Ho Kobeha ka Pono) | 200*12 limilimithara | Boholo ba Boitsebiso (Ho Kobeha ka Ho Otloloha) | 120*12 limilimithara |

| Lebelo le phahameng la ho Koba hlooho (m/min) | 5 (Mokhoa o potlakileng)/1.25 (Mokhoa o butle) | Angle e Kolobehang ea Max (degree) | 90 |

| Lebelo le phahameng la Material lateral block (m/min) | 15 | Stoke of Material lateral block (X Axis) | 2000 |

| Beng Precision (degree) | Matšeliso a iketsang <±0.5Puseletso ka letsoho <±0.2 | Bophara bo Kobehang ba Min U-shape (mm) | 40 (Hlokomela: ka kopo ikopanye le k'hamphani ea rona ha u hloka mofuta o monyane) |