Theko e Khethehileng bakeng sa Fektheri Direct Price Metal Sheet Stainless Steel Fabrication Beng Stamping Precision Aluminium Welding Processing

Re lula le moea oa rona oa k'hamphani oa "Boleng, Ts'ebetso, Boqapi le Botšepehi". Re ikemiselitse ho theha boleng bo eketsehileng bakeng sa bareki ba rona ka lisebelisoa tsa rona tse ngata, mechini e tsoetseng pele, basebetsi ba nang le boiphihlelo le litharollo tse ntlehali bakeng sa Theko e Khethehileng bakeng sa Fektheri ea Direct Price Metal Sheet Stainless Steel Fabrication Benging Stamping Precision Aluminium Welding Processing, Re amohela bareki ba bacha le ba khale ba tsoang mekhoeng eohle ea bophelo ho ikopanya le rona bakeng sa likamano tsa khoebo le katleho e tlang!

Re lula le moea oa rona oa k'hamphani oa "Boleng, Ts'ebetso, Boqapi le Botšepehi". Re ikemiselitse ho theha boleng bo eketsehileng bakeng sa bareki ba rona ka lisebelisoa tsa rona tse ngata, mechini e tsoetseng pele, basebetsi ba nang le boiphihlelo le tharollo e ntlehali bakeng saChina Custom Processing Laser Cutting Form le Zinc Plated Brass Weld Working, Re labalabela ka tieo ho sebelisana le bareki lefatšeng ka bophara. Re lumela hore re ka u khotsofatsa ka thepa ea rona ea boleng bo holimo le tšebeletso e phethahetseng. Re boetse re amohela bareki ka mofuthu ho etela k'hamphani ea rona le ho reka tharollo ea rona.

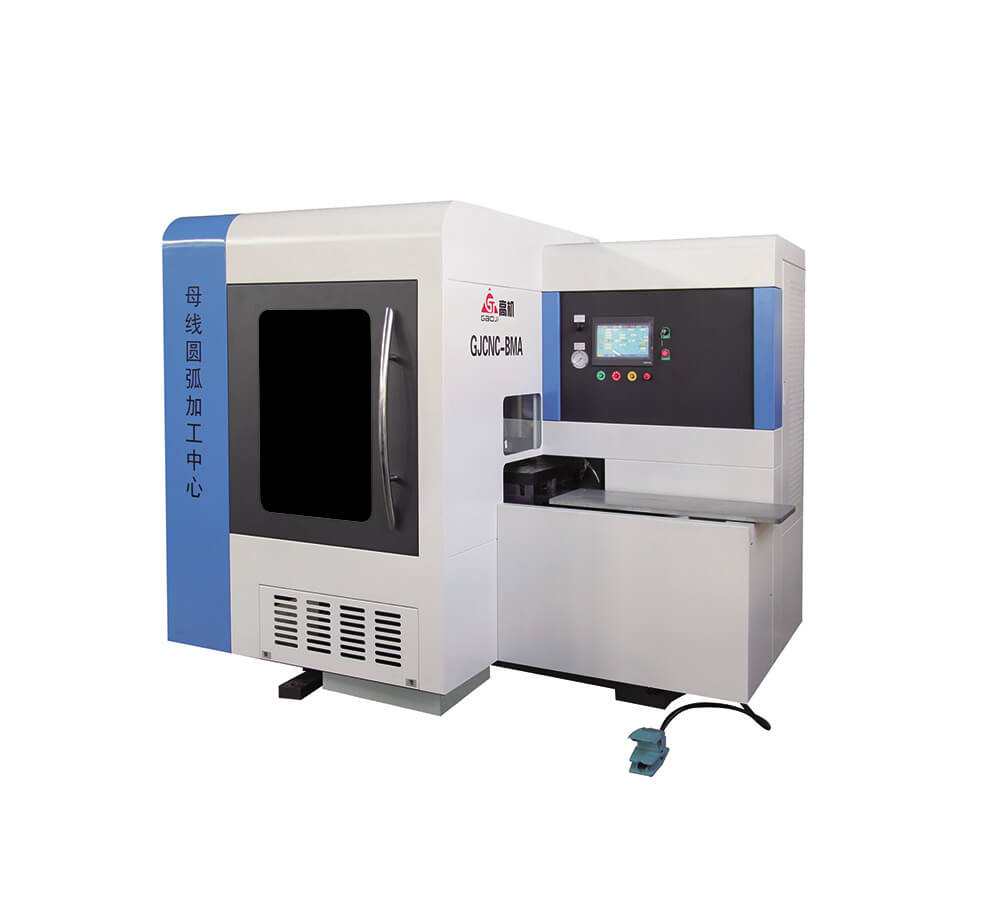

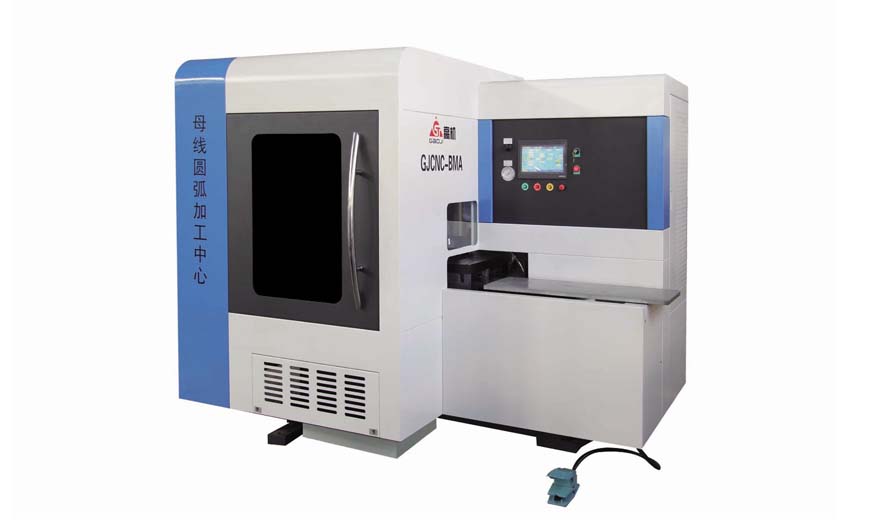

Lintlha tsa Sehlahisoa

Mochini oa ho sila oa libese oa CNC o sebetsa haholo ho fillet ea milling le fillet e kholo ka har'a bese. E hlahisa khoutu ea lenaneo ka bo eona ebe e fetisetsa khoutu ho lisebelisoa ho latela litlhoko tse hlahang ho busbar le tlhahiso ea data skrineng sa ponts'o. E bonolo ho sebetsa mme e khona ho etsa mochini oa busbar arc ka ponahalo e ntle.

Molemo

Mochine ona o sebelisetsoa ho etsa likarolo tsa arc machining bakeng sa lihlooho tsa busbar ka H≤3-15mm, w≤140mm le L≥280mm.

Hlooho ea bar e tla etsoa ka mochine ho sebopeho se nang le sebopeho se tsitsitseng.

Li-clamp li sebelisa theknoloji ea "auto centering" ho hatisa hlooho hantle sebakeng sa ho beha matla.

Booster e sebelisoa hloohong e hatellang ho boloka botsitso ba sesebediswa sa mosebetsi, ho fana ka phello e ntle ea machining holim'a metsi.

Sets'oants'o sa lisebelisoa sa BT40 sa lefats'e se sebelisoa bakeng sa phetisetso e bonolo ea blade, ho tiea ho hoholo le ho nepahala ho phahameng.

Mochini ona o sebelisa likurufu tsa bolo tse nepahetseng haholo le litataiso tsa mela. Ho khethiloe liporo tse boima tsa boholo bo boholo ho fana ka mokhoa o tsitsitseng oa mochine oohle, ho fokotsa ho sisinyeha le lerata, ho ntlafatsa boleng ba mosebetsi le ho netefatsa ho nepahala le ho sebetsa hantle haholo.

U sebelisa likarolo tsa lihlahisoa tse tummeng tsa malapeng le tsa lefats'e, mochine ona o na le nako e telele ea tšebeletso 'me o ka tiisa boleng bo phahameng.

Lenaneo le sebelisitsoeng mochining ona ke software e kenelletseng ea li-graphics programming e ntlafalitsoeng ke k'hamphani ea rona, e hlokomelang boits'oaro ba mananeo. Mosebeletsi ha a tlameha ho utloisisa likhoutu tse fapaneng, hape ha a tlameha ho tseba ho sebelisa setsi sa machining sa setso. Opereishene e tlameha feela ho kenya likarolo tse 'maloa ka ho bua ka litšoantšo,' me lisebelisoa li tla iketsetsa likhoutu tsa mochine. Ho nka nako e khuts'oane ho feta lenaneo la matsoho le ho felisa monyetla oa phoso ea khoutu e bakoang ke mananeo a matsoho.

Busbar e entsoeng ka mochine ona e shebahala hantle, ntle le ho ntša ntlha, e fokotsa boholo ba khabinete ho boloka sebaka le ho fokotsa ka mokhoa o tsotehang tšebeliso ea koporo.

Re lula le moea oa rona oa k'hamphani oa "Boleng, Ts'ebetso, Boqapi le Botšepehi". Re ikemiselitse ho theha boleng bo eketsehileng bakeng sa bareki ba rona ka lisebelisoa tsa rona tse ngata, mechini e tsoetseng pele, basebetsi ba nang le boiphihlelo le litharollo tse ntlehali bakeng sa Theko e Khethehileng bakeng sa Fektheri ea Direct Price Metal Sheet Stainless Steel Fabrication Benging Stamping Precision Aluminium Welding Processing, Re amohela bareki ba bacha le ba khale ba tsoang mekhoeng eohle ea bophelo ho ikopanya le rona bakeng sa likamano tsa khoebo le katleho e tlang!

Theko e khethehileng bakeng saChina Custom Processing Laser Cutting Form le Zinc Plated Brass Weld Working, Re labalabela ka tieo ho sebelisana le bareki lefatšeng ka bophara. Re lumela hore re ka u khotsofatsa ka thepa ea rona ea boleng bo holimo le tšebeletso e phethahetseng. Re boetse re amohela bareki ka mofuthu ho etela k'hamphani ea rona le ho reka tharollo ea rona.

Tlhophiso

| Boholo (mm) | Boima (kg) | Boholo ba Tafole ea Mosebetsi (mm) | Mohloli oa Moea (Mpa) | Kakaretso ea Matla (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Tekheniki Parameters

| Moter Power (kw) | 7.5 | Servo Power (kw) | 2*1.3 | Max Torpue (Nm) | 62 |

| Tool Holder Model | BT40 | Diameter ya Tool (mm) | 100 | Lebelo la Spindle (RPM) | 1000 |

| Bophara ba Lintho (mm) | 30-140 | Nako e Nyenyane ea Bolelele (mm) | 110 | Botenya ba Lintho (mm) | 3 ~ 15 |

| X-Axis Stoke (mm) | 250 | Y-Axis Stoke (mm) | 350 | Lebelo la Boemo bo Potlakileng (mm/min) | 1500 |

| Sekhahla sa Ballscrew (mm) | 10 | Ho nepahala ha boemo (mm) | 0.03 | Lebelo la ho Fepa (mm/min) | 1200 |