Tlhahlobo ea Boleng bakeng sa Mochini oa ho Seha oa Busbar o Iketsang ka Botlalo o Phahameng oa CNC bakeng sa Koporo

Re ikemiselitse ho fumana ho senyeha ha boleng bo holimo molokong le ho fana ka lits'ebeletso tse sebetsang ka ho fetisisa ho bareki ba lehae le ba kantle ho naha ka pelo eohle bakeng sa Tlhahlobo ea Boleng bakeng sa Mochini oa ho Seha oa CNC o Iketsang ka Botlalo bo Phahameng oa ho Sebetsa ka Botlalo oa Kopi, Ha u ntse u tsoma hang le ka ho sa feleng Boleng bo holimo ka theko e ntle le ka nako e loketseng. Ikopanye le rona.

Re ikemiselitse ho fumana ho senyeha ha boleng bo holimo molokong ona le ho fana ka lits'ebeletso tse sebetsang hantle ho bareki ba lehae le ba kantle ho naha ka pelo eohle bakeng saMochini oa ho Sibolla Libasbar oa Chaena le Mochini oa Libasbar oa 3 ho 1, Re lumela ho theheng likamano tse ntle tsa bareki le tšebelisano-'moho e ntle bakeng sa khoebo. Tšebelisano-'moho e haufi le bareki ba rona e re thusitse ho theha liketane tse matla tsa phepelo le ho kotula melemo. Thepa ea rona e re fumanetse kamohelo e pharaletseng le khotsofalo ea bareki ba rona ba bohlokoa lefatšeng ka bophara.

Lintlha tsa Sehlahisoa

GJCNC-BP-50 ke sesebelisoa sa profeshenale se etselitsoeng ho sebetsana le busbar ka katleho le ka nepo.

Nakong ea ts'ebetso ea lisebelisoa tsena e ka nkela li-clamp sebaka ka bohona, e leng se sebetsang hantle haholo-holo bakeng sa busbar e telele. Ka li-dies tseo tsa ts'ebetso laeboraring ea lisebelisoa, lisebelisoa tsena li ka sebetsana le busbar ka ho phunya (lesoba le chitja, lesoba le lelelele jj), ho khabisa, ho kuta, ho grooving, ho seha sekhutlo se nang le li-fillet le tse ling. Mosebetsi o felileng o tla tlisoa ke conveyor.

Sesebelisoa sena se ka tsamaellana le CNC bender mme sa etsa mohala wa tlhahiso ya ts'ebetso ya busbar.

Sebapali se ka Sehloohong

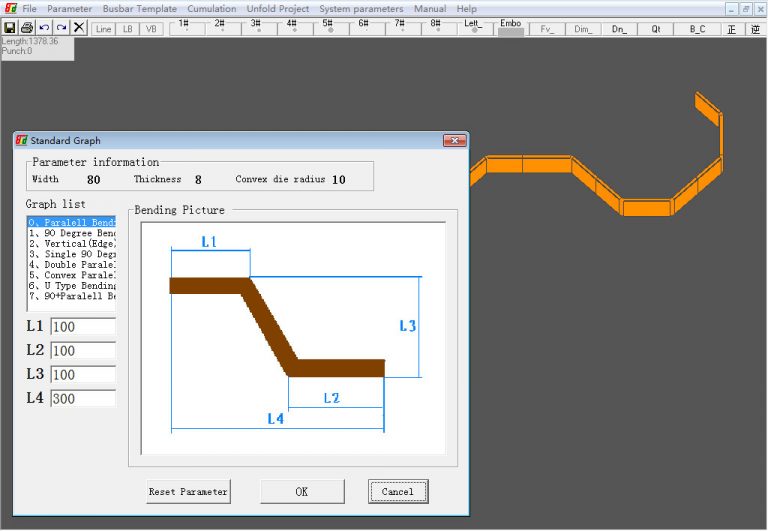

GJ3D / software ea mananeo

GJ3D ke software e khethehileng e thusang moralo oa ts'ebetso ea busbar. E ka hlophisa khoutu ea mochini ka bo eona, ea bala letsatsi le leng le le leng le sebetsang, 'me ea u bontša ketsiso ea ts'ebetso eohle e tla hlahisa phetoho ea busbar mohato ka mohato ka ho hlaka. Litlhaku tsena li entse hore ho be bonolo le ho ba matla ho qoba ho ngola khoutu ka letsoho ka puo ea mochini. 'Me e khona ho bontša ts'ebetso eohle le ho thibela ka katleho tšenyo ea thepa e bakoang ke ho kenya ho fosahetseng.

Ka lilemo tse ngata, k'hamphani e bile moetapele oa ho sebelisa mokhoa oa litšoantšo oa 3D indastering ea ts'ebetso ea busbar. Joale re ka u fa software e ntle ka ho fetisisa ea taolo le moralo oa cnc ka Se-Asia.

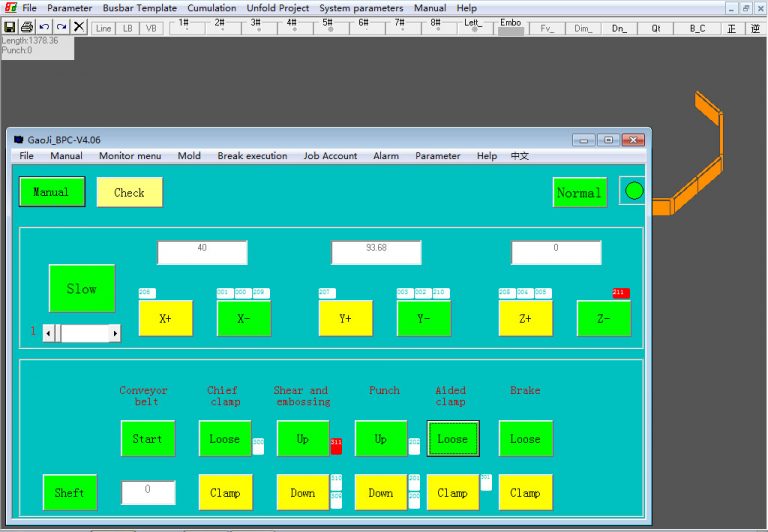

Sebopeho sa khomphutha sa motho

E le ho hlahisa boiphihlelo bo betere ba ts'ebetso le tlhaiso-leseling e molemo haholoanyane. Sesebelisoa se na le RMTP ea 15” e le sebopeho sa khomphutha ea motho. Ka sesebelisoa sena u ka ba le tlhaiso-leseling e hlakileng ea ts'ebetso eohle ea tlhahiso kapa alamo efe kapa efe e ka etsahala 'me ua laola sesebelisoa ka letsoho le le leng.

Haeba o hloka ho fetola tlhahisoleseding ea ho seta sesebelisoa kapa liparamente tsa motheo tsa die. U ka boela ua kenya letsatsi ka yuniti ena.

Meaho ea Mekaniki

E le ho theha sebopeho sa mechini se tsitsitseng, se sebetsang hantle, se nepahetseng le se phelang nako e telele, re khetha screw e nepahetseng ea bolo e phahameng, tataiso e nepahetseng ea mola o otlolohileng ke Taiwan HIWIN le sistimi ea servo ke YASKAWA hammoho le sistimi ea rona e ikhethang ea li-clamp tse peli. Tsena tsohle tse kaholimo li etsa sistimi ea phetisetso e ntle kamoo u hlokang.

Re ntshetsa pele lenaneo la ho nkela sebaka ka bohona e le ho etsa hore sistimi ya clamp e sebetse hantle haholoholo bakeng sa ts'ebetso e telele ya busbar, mme hape e ka fokotsa mosebetsi wa mosebedisi ka botlalo. Ho hlahisa boleng bo eketsehileng bakeng sa bareki ba rona.

Ho na le mefuta e 'meli:

GJCNC-BP-50-8-2.0/SC (Ho phunya ka ho tjhesa tse tsheletseng, ho kuta, ho tobetsa)

GJCNC-BP-50-8-2.0/C (Ho phunya ka ho phunya ka makhetlo a robeli, ho kuta ka lehare)

U ka khetha mehlala eo u e hlokang

Ho paka kantle ho naha

Re ikemiselitse ho fumana ho senyeha ha boleng bo holimo molokong le ho fana ka lits'ebeletso tse sebetsang ka ho fetisisa ho bareki ba lehae le ba kantle ho naha ka pelo eohle bakeng sa Tlhahlobo ea Boleng bakeng sa Mochini oa ho Seha oa CNC o Iketsang ka Botlalo bo Phahameng oa ho Sebetsa ka Botlalo oa Kopi, Ha u ntse u tsoma hang le ka ho sa feleng Boleng bo holimo ka theko e ntle le ka nako e loketseng. Ikopanye le rona.

Tlhahlobo ea Boleng bakeng saMochini oa ho Sibolla Libasbar oa Chaena le Mochini oa Libasbar oa 3 ho 1, Re lumela ho theheng likamano tse ntle tsa bareki le tšebelisano-'moho e ntle bakeng sa khoebo. Tšebelisano-'moho e haufi le bareki ba rona e re thusitse ho theha liketane tse matla tsa phepelo le ho kotula melemo. Thepa ea rona e re fumanetse kamohelo e pharaletseng le khotsofalo ea bareki ba rona ba bohlokoa lefatšeng ka bophara.

Li-parameter tse ka sehloohong tsa tekheniki

| Tekanyo (mm) | 7500*2980*1900 | Boima (kg) | 7600 | Setifikeiti | CE ISO | ||

| Matla a ka Sehloohong (kw) | 15.3 | Motlakase oa ho kenya | 380/220V | Mohloli oa Matla | haeteroliki | ||

| Matla a ho Hlahisa (kn) | 500 | Lebelo la ho phunya (hpm) | 120 | Axis ea Taolo | 3 | ||

| Boholo ba Thepa (mm) | 6000*200*15 | Ho Shoa ha Max Punching | 32mm (Botenya ba thepa e ka tlase ho 12mm) | ||||

| Lebelo la Sebaka(Sehlopha sa X) | 48m/motsotso | Sekoti sa Silindara sa ho Putla | 45mm | Ho Pheta-pheta ha Sebaka | ± 0.20mm/m | ||

| Setoroko se Seholo(mm) | Sekhahla sa XSekahare sa YSekahare sa Z | 2000530350 | CheleteofMafu | Ho otla ka ho otlaHo kutaHo khabisa ka mongolo o motsho | 6/81/11/0 | ||

Tlhophiso

| Likarolo tsa Taolo | Likarolo tsa Phetiso | ||

| PLC | OMRON | Tataiso e nepahetseng ea mola | HIWIN ea Taiwan |

| Li-sensor | Motlakase oa Schneider | Sekurufu sa bolo se nepahetseng (letoto la bone) | HIWIN ea Taiwan |

| Konopo ea Taolo | OMRON | Tšehetso ea screw ea bolo | NSK ea Majapane |

| Skrine se thetsoang | OMRON | Likarolo tsa haeteroliki | |

| Khomphutha | Lenovo | Valve ea Electromagnetic e nang le khatello e phahameng | Italy |

| Sehokelo sa AC | ABB | Phaephe ea khatello e phahameng | Italy MANULI |

| Sehahi sa Potoloho | ABB | Pompo ea khatello e phahameng | Italy |

| Enjene ea Servo | YASKAWA | Software ea taolo le software ea tšehetso ea 3D | GJ3D (software ea tšehetso ea 3D e entsoeng ke k'hamphani ea rona kaofela) |

| Mokhanni oa Servo | YASKAWA | ||