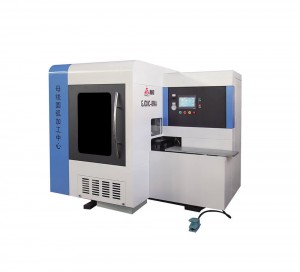

Botumo bo Botle ba Mosebelisi bakeng sa Ho Sebetsa ka ho Sebetsa ka Lisebelisoa tse Hloahloa tsa CNC Machining, Ho Sebetsa ka Mochini oa ho Fetola le ho Sila oa Tšepe e sa Khaotseng

Hangata re tsoela pele ka molao-motheo oa "Boleng Ho qala ka, Prestige Supreme". Re ikemiselitse ka botlalo ho fa bareki ba rona litharollo tse ntle tse theko e phahameng, ho fana ka thepa kapele le tšehetso e nang le boiphihlelo bakeng sa Botumo bo Botle ba Basebelisi bakeng sa Precision Hardware CNC Machining Four-Axis Five-Axis CNC Lathe Stainless Steel Turning and Milling Centering Machine Processing, Rea u amohela hore u ikopanye le rona tseleng ena ea ho theha khoebo e atlehileng le e sebetsang hantle hammoho.

Hangata re tsoela pele ka molao-motheo o reng “Boleng ba ho qala, Prestige Supreme”. Re ikemiselitse ka botlalo ho fa bareki ba rona litharollo tse ntle tse theko e phahameng, phano e potlakileng le tšehetso e nang le boiphihlelo bakeng saKarolo ea Machining e Nepahetseng le Karolo e Entsoeng ka Mechini, Re tšepa hore re ka theha tšebelisano-'moho ea nako e telele le bareki bohle, 'me re tšepa hore re ka ntlafatsa tlholisano le ho fihlela boemo ba ho hapa bohle hammoho le bareki. Re amohela bareki ba tsoang lefats'eng lohle ka tieo ho ikopanya le rona bakeng sa eng kapa eng eo u e batlang! Re amohela bareki bohle ba lapeng le ba kantle ho naha ho etela fektheri ea rona. Re tšepa ho ba le likamano tsa khoebo tse hapang bohle le uena, le ho theha bokamoso bo betere.

Litšobotsi tsa mantlha tsa ts'ebetso

• Setsi sa ho sebetsa ka khabinete ea lesale se ka phethela ka bohona sebaka sa koporo sa mahlakore a mararo sa mahlakore a mangata. Angle ea ho kobeha ka bohona, ho phunya ha CNC, ho batalatsa hanngoe, ho shear ha chamfering le theknoloji e 'ngoe ea ts'ebetso;

• Sekhutlo sa mochini se kobehang se laoloa ka bohona, tataiso ea bolelele ba molamu oa koporo e beoa ka bohona, tataiso ea selikalikoe sa molamu oa koporo e potoloha ka bohona, ketso ea ts'ebetso e tsamaisoa ke enjene ea servo, taelo ea tlhahiso e laoloa ke sistimi ea servo, 'me ho kobeha ha sebaka ka likhutlo tse ngata hoa phethahala e le kannete.

• Mochini o etsa ts'ebetso ea ho beha maemo ka boiketsetso ha bara ea koporo e bataletse, e sehiloe, e phunngoa le ho phunngoa, ka ts'ebetso e bonolo le ho nepahala ho hoholo ha mechini, ho fokotsa bothata le phoso ea ho bala ka letsoho le taolo ea tataiso ea Angle.

• Ka ho sebedisa sebopeho sa motho le mochini, bapisa setshwantsho sa mosebetsi, diparamitha tse amanang le ho kenya, Angle, tlhophiso ya data e bonolo, e potlakileng, e nepahetseng haholo.

• Mochini o amohela phepo e thusang ka letsoho le ho fepa ka molamu oa koporo ka boiketsetso ho phethahatsa ts'ebetso e tsoelang pele ea othomathiki.

• Mochini o na le screw ea bolo e nepahetseng haholo le seporo sa tataiso se otlolohileng ho netefatsa ho nepahala ho hoholo le katleho e phahameng.

• Mochini o na le screw ea bolo e nepahetseng haholo le seporo sa tataiso se otlolohileng ho netefatsa ho nepahala ho hoholo le katleho e phahameng.

• Likarolo tsa motlakase tsa mochini li entsoe ka lihlahisoa tse tsebahalang lapeng le kantle ho naha, tse nang le bophelo bo bolelele ba tšebeletso le netefatso ea boleng.

• Sebetsa lithupa tsa koporo ka har'a moeli oa ∅8 ho isa ho ∅25. Bolelele ba ho batalatsa hang feela: 50mm,

Li-parameter tse ka sehloohong tsa tekheniki

| Sehlooho | Yuniti | Lintlha | |

| Ho kobeha | Matla a tloaelehileng | kN | 260 |

| Ho nepahala ha Angle ea ho kobeha | Palo ea likhato | <± 0.3 | |

| Phoso ea ho potoloha ha sebaka | Palo ea likhato | <± 0.3 | |

| Sekoti sa axial | mm | 1500 | |

| Ho nepahala ha bolelele ba ho fepa | mm | 0.2 | |

| Molamu oa koporo o lumelletsoeng | mm | Ф8~Ф25 | |

| Angle e fokolang ea ho reteleha | Palo ea likhato | 70° | |

| Phoso ea bolelele ba ho kobeha | mm | 0.5 | |

| Angle ea ho potoloha ha axial | Palo ea likhato | 360°(<±0.2°) | |

| Ho nepahala ha boemo bo pheta-phetoang | mm | ± 0.1 | |

| Matla a servo kaofela | kW | 2.3 | |

| Ho batalla, ho kuta, ho phunya, ho shapa | Matla a tloaelehileng | kN | 1000 |

| Molamu oa koporo o lumelletsoeng | mm | Ф8~Ф25 | |

| Teke e phahameng ka ho fetisisa | mm | Ф32×26 | |

| Bolelele bo phahameng ka ho fetisisa ba ho batalatsa ka nako e le 'ngoe | mm | 50 | |

| Phoso ea ho batalla ha motsamao | mm | 0.1 | |

| Phoso ea bolelele ba ho batalla | mm | 0.3 | |

| Bolelele ba thepa e setseng | mm | 150 | |

| Boima ba mochini | T | 3.36 | |

| Boholo ba mochini (bolelele * bophara * bophahamo) | mm | 3200*1500*2200 | |

| Matla ohle a phepelo | kW | 11.05 | |

Hangata re tsoela pele ka molao-motheo oa "Boleng Ho qala ka, Prestige Supreme". Re ikemiselitse ka botlalo ho fa bareki ba rona litharollo tse ntle tse theko e phahameng, ho fana ka thepa kapele le tšehetso e nang le boiphihlelo bakeng sa Botumo bo Botle ba Basebelisi bakeng sa Precision Hardware CNC Machining Four-Axis Five-Axis CNC Lathe Stainless Steel Turning and Milling Centering Machine Processing, Rea u amohela hore u ikopanye le rona tseleng ena ea ho theha khoebo e atlehileng le e sebetsang hantle hammoho.

Hangata re tsoela pele ka molao-motheo oa "Boleng Ho qala ka, Prestige Supreme". Re ikemiselitse ka botlalo ho fa bareki ba rona litharollo tse ntle tse theko e phahameng, ho fana ka thepa kapele le tšehetso e nang le boiphihlelo bakeng sa Botumo bo Botle ba Basebelisi bakeng sa Precision Hardware CNC Machining Four-Axis Five-Axis CNC Lathe Stainless Steel Turning and Milling Centering Machine Processing, Rea u amohela hore u ikopanye le rona tseleng ena ea ho theha khoebo e atlehileng le e sebetsang hantle hammoho.

Botumo bo Botle ba Mosebelisi bakeng saKarolo ea Machining e Nepahetseng le Karolo e Entsoeng ka Mechini, Re tšepa hore re ka theha tšebelisano-'moho ea nako e telele le bareki bohle, 'me re tšepa hore re ka ntlafatsa tlholisano le ho fihlela boemo ba ho hapa bohle hammoho le bareki. Re amohela bareki ba tsoang lefats'eng lohle ka tieo ho ikopanya le rona bakeng sa eng kapa eng eo u e batlang! Re amohela bareki bohle ba lapeng le ba kantle ho naha ho etela fektheri ea rona. Re tšepa ho ba le likamano tsa khoebo tse hapang bohle le uena, le ho theha bokamoso bo betere.

Li-parameter tse ka sehloohong tsa tekheniki

| Tlhaloso | Yuniti | Paramethara | |

| Yuniti ea ho Koba | Matla | kN | 200 |

| Ho Nepahala ha ho Kobeha | 度 | <±0.3* | |

| Stroke ea Axial ea mantlha | mm | 1500 | |

| Boholo ba Thupa | mm | 8~420 | |

| Angle e Kobehileng e Nyenyane | Tekanyo | 70 | |

| Angle ea ho Potoloha | tekanyo | 360 | |

| Matla a Motlakase | kw | 1.5 | |

| Matla a Servo | kw | 2.25 | |

| Yuniti ea ho Seha | Matla | kN | 300 |

| Matla a Motlakase | kW | 4 | |

| Boholo ba molamu | mm | 8~420 | |

| Yuniti ea ho phunya | Matla | kN | 300 |

| Boholo ba ho Otla ka ho Fetisisa | mm | 26×32 | |

| Matla a Motlakase | kw | 4 | |

| Yuniti ea Khatiso e bataletseng | Matla | kN | 600 |

| Bolelele bo phahameng ba ho tobetsa |

| 4s | |

| Matla a Motlakase | kw | 4 | |

| Yuniti ea Chamfer | Yuniti | kN | 300 |

| Matla a Motlakase | kw | 4 | |