Theko ea Fektheri Bakeng sa Thekiso e Tobileng ea Fektheri 99.99% Brass Copper Plate e Ikhethileng Boholo ba Copper Plate Sheet Coil

Ho ntlafatsa mokhoa oa tsamaiso ka mokhoa o tsitsitseng ka lebaka la molao oa "ka tieo, bolumeli bo babatsehang le boleng bo holimo ke motheo oa nts'etsopele ea khoebo", re monya ka botlalo bohlokoa ba thepa e amanang le eona machabeng, 'me re lula re fumana thepa e ncha ho khotsofatsa litlhoko tsa bareki bakeng sa Theko ea Fektheri Bakeng sa Thekiso e Tobileng ea Fektheri 99.99% Brass Copper Plate Size Copper Plate Sheet Coil, Re hlompha molao-motheo oa rona oa Botšepehi khamphaning, pele tšebeletsong 'me re tla etsa sohle se matleng a rona ho fa bareki ba rona lihlahisoa le litharollo tsa boleng bo holimo le tšehetso e kholo.

Ho ntlafatsa mokhoa oa tsamaiso ka mokhoa o tsitsitseng ka lebaka la molao oa "ka tieo, bolumeli bo botle le boleng bo holimo ke motheo oa nts'etsopele ea khoebo", re monya ka botlalo bohlokoa ba thepa e amanang le eona machabeng, 'me re lula re fumana thepa e ncha ho khotsofatsa litlhoko tsa bareki bakeng saPoleiti ea Koporo ea Chaena le Leqephe la Koporo, E le ho fihlela litlhoko tse ling tsa 'maraka le nts'etsopele ea nako e telele, fektheri e ncha ea lisekoere-mithara tse 150,000 e ntse e hahuoa, e ka sebelisoang ka 2014. Ebe re tla ba le bokhoni bo boholo ba ho hlahisa. Ehlile, re tla tsoela pele ho ntlafatsa sistimi ea litšebeletso ho fihlela litlhoko tsa bareki, re tlise bophelo bo botle, thabo le botle ho bohle.

Lintlha tsa Sehlahisoa

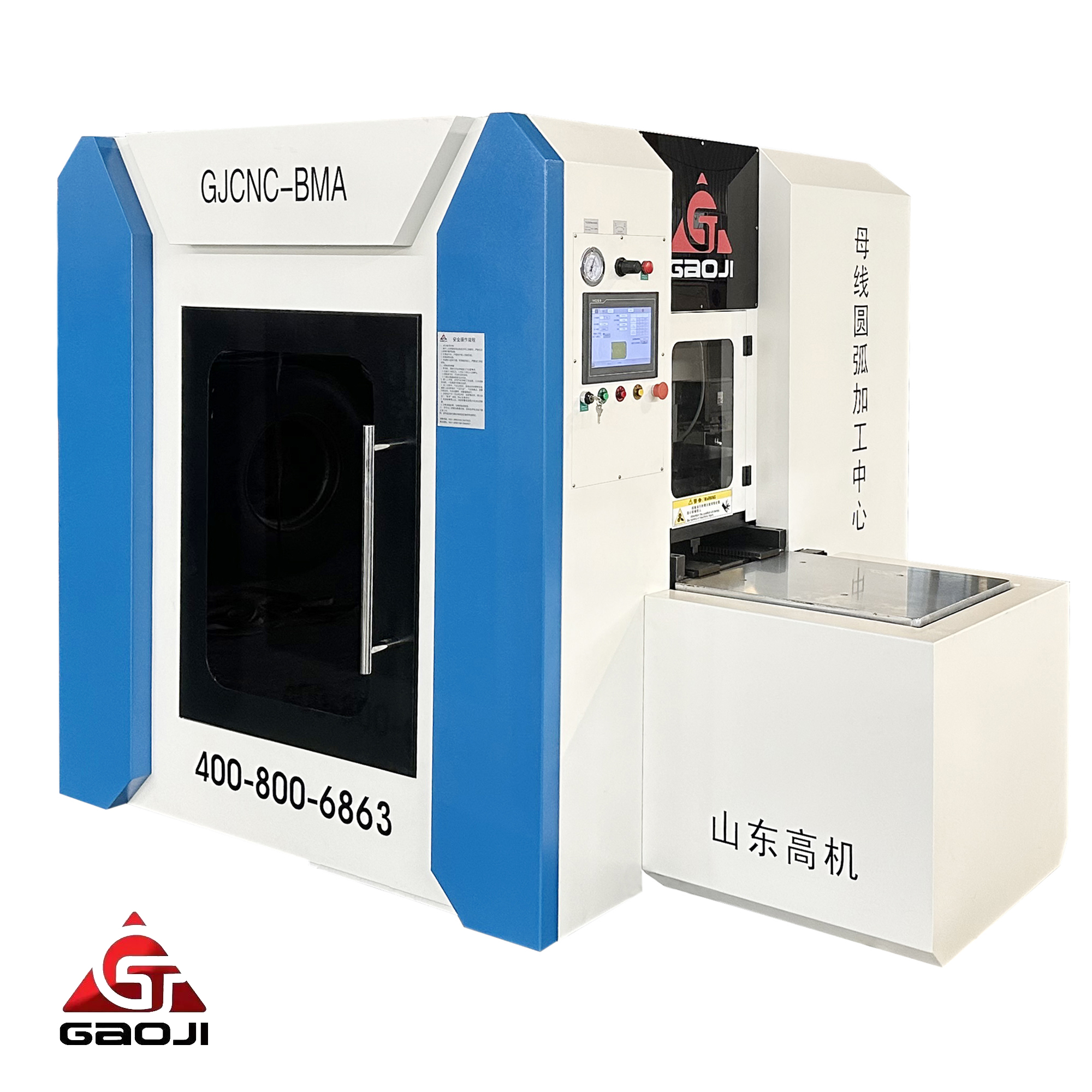

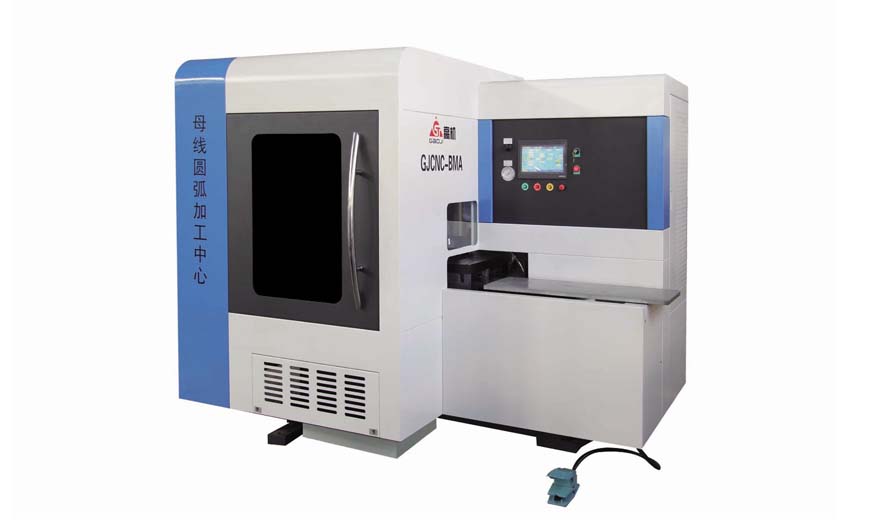

Mochini oa ho sila oa busbar oa CNC o sebetsa haholo-holo ka har'a fillet ea ho sila le fillet e kholo ka har'a busbar. O hlahisa khoutu ea lenaneo ka bohona 'me o fetisetsa khoutu ho lisebelisoa ho latela litlhoko tse hlalositsoeng ho busbar le tlhahiso ea data skrineng sa ponts'o. Ho bonolo ho e sebelisa 'me e ka sebelisa arc ea busbar e sebetsang ka mokhoa o motle.

Molemo

Mochini ona o sebelisetsoa ho etsa machining ea arc ea likarolo bakeng sa lihlooho tsa busbar tse nang le H≤3-15mm, w≤140mm le L≥280mm.

Hlooho ea bare e tla etsoa ka mochini ho latela sebopeho se nang le sebopeho se tsitsitseng.

Li-clamp li sebelisa theknoloji ea ho tsepamisa bohareng ka boiketsetso ho hatella hlooho ea ho tobetsa hantle sebakeng sa ho jara matla.

Sesebelisoa sa ho matlafatsa se sebediswa hloohong ya ho tobetsa ho tiisa botsitso ba sesebediswa sa ho sebetsa, e leng se fanang ka phello e betere ya bokahodimo ba ho sebetsa.

Sesebediswa sa maemo a lefatshe sa BT40 se sebediswa bakeng sa ho nkela lehare sebaka habonolo, ho tiya hanyane le ho nepahala ho hoholo.

Mochini ona o sebelisa li-screw tsa bolo tse nepahetseng haholo le litataiso tse otlolohileng. Li-rails tse kholo tse boima tse nang le mojaro o boima li khethiloe ho fana ka ho tiea ho betere ha mochini oohle, ho fokotsa ho thothomela le lerata, ho ntlafatsa boleng ba mosebetsi le ho netefatsa ho nepahala le katleho e phahameng.

Ka ho sebelisa likarolo tsa lihlahisoa tse tummeng tsa lehae le tsa lefats'e, mochini ona o phela nako e telele 'me o ka netefatsa boleng bo holimo.

Lenaneo le sebediswang mochining ona ke software ya mananeo a ditshwantsho a iketsang e kentsweng e ntshetswang pele ke khamphani ya rona, e etsang hore ho be le boiketsetso mananeong. Mosebelisi ha a hloke ho utlwisisa dikhoutu tse fapaneng, leha e le hore o tlameha ho tseba ho sebedisa setsi sa setso sa machining. Mosebelisi o tlameha feela ho kenya diparamitha tse mmalwa ka ho sheba ditshwantsho, mme sesebediswa se tla hlahisa dikhoutu tsa mochini ka boiketsetso. Ho nka nako e kgutshwane ho feta mananeo a letsoho mme ho fedisa bokgoni ba phoso ya khoutu e bakwang ke mananeo a letsoho.

Busbar e entsoeng ka mochini ona e shebahala hantle, ha e na ntlha e ntšang metsi, e fokotsa boholo ba khabinete ho boloka sebaka le ho fokotsa tšebeliso ea koporo ka mokhoa o makatsang.

Ho ntlafatsa mokhoa oa tsamaiso ka mokhoa o tsitsitseng ka lebaka la molao oa "ka tieo, bolumeli bo babatsehang le boleng bo holimo ke motheo oa nts'etsopele ea khoebo", re monya ka botlalo bohlokoa ba thepa e amanang le eona machabeng, 'me re lula re fumana thepa e ncha ho khotsofatsa litlhoko tsa bareki bakeng sa Theko ea Fektheri Bakeng sa Thekiso e Tobileng ea Fektheri 99.99% Brass Copper Plate Size Copper Plate Sheet Coil, Re hlompha molao-motheo oa rona oa Botšepehi khamphaning, pele tšebeletsong 'me re tla etsa sohle se matleng a rona ho fa bareki ba rona lihlahisoa le litharollo tsa boleng bo holimo le tšehetso e kholo.

Theko ea Fektheri Bakeng saPoleiti ea Koporo ea Chaena le Leqephe la Koporo, E le ho fihlela litlhoko tse ling tsa 'maraka le nts'etsopele ea nako e telele, fektheri e ncha ea lisekoere-mithara tse 150,000 e ntse e hahuoa, e ka sebelisoang ka 2014. Ebe re tla ba le bokhoni bo boholo ba ho hlahisa. Ehlile, re tla tsoela pele ho ntlafatsa sistimi ea litšebeletso ho fihlela litlhoko tsa bareki, re tlise bophelo bo botle, thabo le botle ho bohle.

Tlhophiso

| Tekanyo (mm) | Boima (kg) | Boholo ba Tafole ea ho Sebetsa (mm) | Mohloli oa Moea (Mpa) | Matla a Feletseng (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Li-parameter tsa Tekheniki

| Matla a 'Mè (kw) | 7.5 | Matla a Servo (kw) | 2*1.3 | Max Torpue (Nm) | 62 |

| Mohlala oa Setho sa Lisebelisoa | BT40 | Bophara ba Sesebelisoa (mm) | 100 | Lebelo la Spindle (RPM) | 1000 |

| Bophara ba thepa (mm) | 30~140 | Bolelele bo Bonyenyane ba Thepa (mm) | 110 | Botenya ba thepa (mm) | 3~15 |

| Setopo sa X-Axis (mm) | 250 | Stoke ea Y-Axis (mm) | 350 | Lebelo la Boemo bo Potlakileng (mm/min) | 1500 |

| Sekontiri sa bolo (mm) | 10 | Ho nepahala ha Boemo (mm) | 0.03 | Lebelo la ho Fepa (mm/min) | 1200 |