Masimong a litsamaiso tsa motlakase le tlhahiso ea indasteri, "busbar" e tšoana le mohale ea sa bonoeng, ea jereng matla a maholo le ts'ebetso e nepahetseng ka khutso. Ho tloha liteisheneng tse telele ho ea ho lisebelisoa tsa elektroniki tse rarahaneng le tse rarahaneng, ho tloha pelong ea gridi ea motlakase ea litoropo ho ea bohareng ba mela ea tlhahiso e iketsang, busbar, ka mefuta le mesebetsi ea eona e fapaneng, e haha marang-rang a bohlokoa bakeng sa phetiso ea matla le matšoao. 'Me ka theknoloji e tsoetseng pele le boqhetseke bo ikhethang, High Machinery Company e fetohile moetapele oa lisebelisoa tsa ts'ebetso ea busbar, e fanang ka tiisetso e tiileng bakeng sa ts'ebeliso e sebetsang ea li-busbar indastering e fapaneng.

1. Tlhaloso le Bohlokoa ba Libasbars

Ho ya ka pono ya motheo, busbar ke kondaktara e bokellang, e abang, le ho fetisa matla a motlakase kapa matshwao. E tshwana le "tsela e kgolo" potolohong, e hokahanyang disebediswa tse fapaneng tsa motlakase mme e etsa mesebetsi ya ho fetisetsa le ho fetisa motlakase kapa matshwao. Sistiming ya motlakase, mosebetsi wa mantlha wa busbar ke ho bokella tlhahiso ya matla a motlakase ke mehlodi e fapaneng ya motlakase (jwalo ka dijenereithara le di-transformer), le ho a aba makaleng a fapaneng a tshebediso ya motlakase; disebedisweng tsa elektroniki, busbar e ikarabella bakeng sa ho fetisa data le matshwao a taolo pakeng tsa di-chip le di-module tse fapaneng, ho netefatsa tshebetso e tlwaelehileng ya disebediswa.

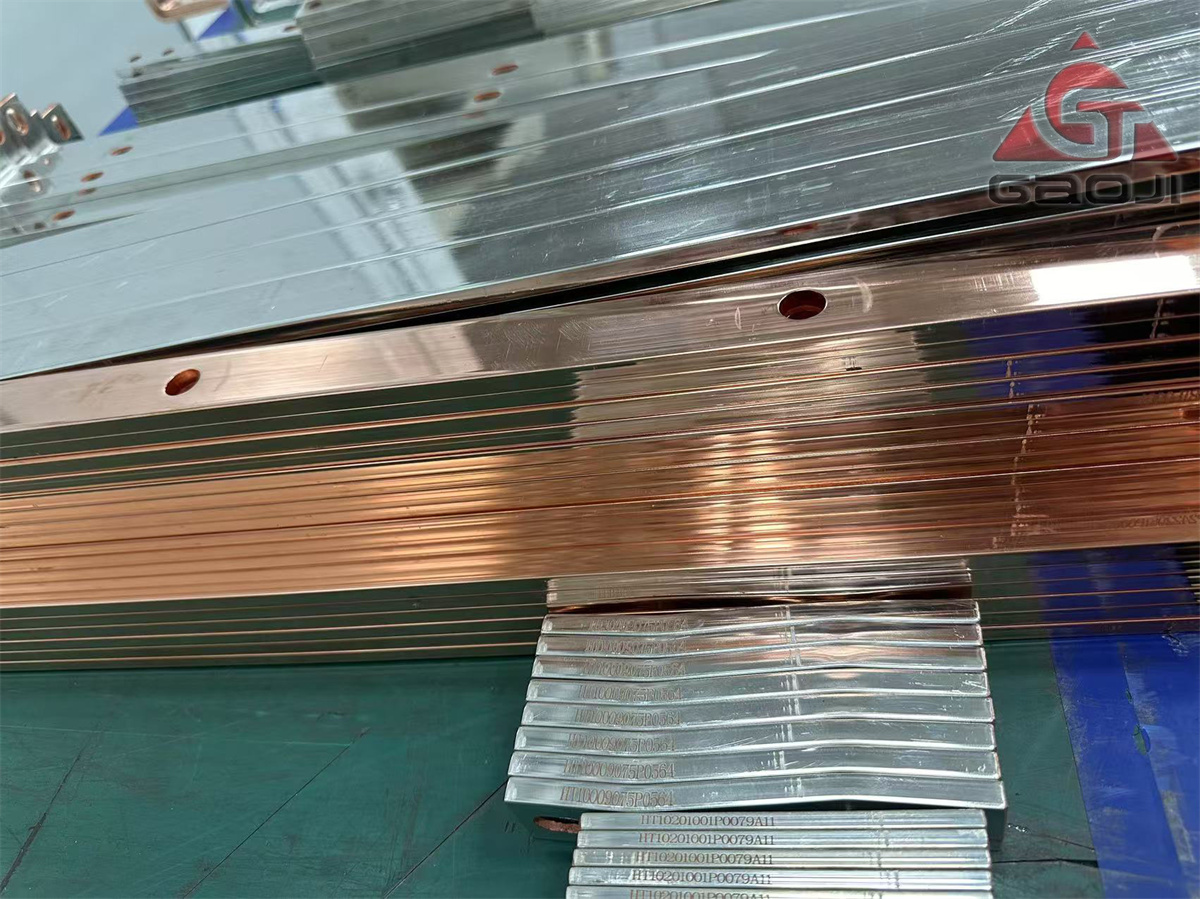

Ho ya ka pono ya thepa, thepa e tlwaelehileng bakeng sa di-busbar e kenyeletsa koporo le aluminium. Koporo e na le bokgoni bo botle ba ho tsamaisa motlakase le ho hanyetsa mafome, tahlehelo e tlase ya phetiso, empa e theko e boima haholo. Hangata e sebediswa maemong ao ho ona ditlhoko tse thata di bewang boleng ba phetiso ya matla a motlakase, jwalo ka disebediswa tsa elektroniki tse nepahetseng le ditsi tsa data tsa maemo a hodimo. Aluminium e na le bongata bo tlase le theko e tlase. Le hoja bokgoni ba yona ba ho tsamaisa motlakase bo le tlase hanyane ho feta ba koporo, e fetoha thepa e kgethwang boenjiniere ba matla moo maqhubu a maholo, dibaka tse telele, le kutlwisiso ya ditjeo di amehang, jwalo ka mela ya phetiso ya motlakase o phahameng le diteishene tse kgolo tse nyane.

Khamphani ea Gaoji e na le kutloisiso e tebileng ea tšusumetso ea thepa ea thepa ea busbar lits'ebetsong. Lisebelisoa tsa eona tse ntlafalitsoeng tsa ts'ebetso ea busbar li ka sebetsana le li-busbar tsa koporo le aluminium ka nepo le ka bokgabane, li fihlela litlhoko tsa ho nepahala ha ts'ebetso le katleho ea bareki ba fapaneng bakeng sa li-busbar, le ho netefatsa ts'ebetso e tsitsitseng ea li-busbar libakeng tse fapaneng tse rarahaneng.

2. Libese tse Sistimi ea Motlakase: Setsi sa Motheo sa Gridi

Sistimi ea motlakase, busbar ke karolo ea bohlokoa ea liteishene tse nyane le liteishene tsa kabo. Ho ea ka boemo ba motlakase le ts'ebetso, e ka aroloa ka busbar ea motlakase o phahameng le busbar ea motlakase o tlase. Boemo ba motlakase ba busbar ea motlakase o phahameng hangata ke li-kilovolts tse 35 kapa ho feta, 'me e sebelisoa haholo-holo lifemeng tsa motlakase le liteisheneng tse nyane tsa motlakase o phahameng haholo, e leng se etsang mosebetsi oa ho bokella le ho fetisa matla a motlakase a maholo libakeng tse telele. Moralo le ts'ebetso ea eona li ama ka kotloloho botsitso ba li-grid tsa motlakase tsa libaka le tsa naha. Busbar ea motlakase o tlase e ikarabella bakeng sa ho aba matla a motlakase ka mokhoa o sireletsehileng le o sebetsang ho basebelisi ba ho qetela joalo ka lifeme tsa indasteri, meaho ea khoebo le libaka tsa bolulo.

Ha ho tluoa tabeng ea sebopeho sa sebopeho, li-busbar tsa motlakase li arotsoe ka li-busbar tse thata le li-busbar tse bonolo. Li-busbar tse thata hangata li sebelisa li-conductor tsa tšepe tse khutlonnetsepa, tse bōpehileng joaloka torso kapa tse nang le tšubu, tse tsitsitseng le ho kenngoa ka li-insulator. Li na le litšobotsi tsa sebopeho se kopaneng, bokhoni bo boholo ba ho jara motlakase le matla a phahameng a mechini, 'me li loketse li-substation tsa ka tlung le lisebelisoa tsa kabo tse nang le sebaka se fokolang le maqhubu a maholo; li-busbar tse bonolo hangata li entsoe ka likhoele tse ngata tsa lithapo tse sothehileng, joalo ka terata ea aluminium e koahetsoeng ka tšepe, e leketlileng foreiming ke likhoele tsa insulator. Li na le melemo ea litšenyehelo tse tlase, ho kenya habonolo le ho ikamahanya le libaka tse kholo, 'me hangata li sebelisoa li-substation tsa kantle tse nang le motlakase o phahameng.

Khamphani ea Gaoji e fana ka litharollo tse felletseng bakeng sa ts'ebetso ea li-busbar tsa sistimi ea motlakase. Sehlahisoa sa eona se seholo, mohala o bohlale oa ts'ebetso ea li-busbar, o nolofalletsa ts'ebetso eohle ea kopano ea li-busbar - ho tloha ho lata le ho kenya thepa ka boiketsetso, ho ea ho ho phunya, ho tšoaea, ho chencha, ho kobeha, jj. - ho iketsahalla ka botlalo. Kamora hore litaelo tsa ts'ebetso li huloe ke seva 'me li fanoe, sehokelo se seng le se seng se sebetsa haufi-ufi. Mosebetsi o mong le o mong o ka sebetsoa ka motsotso o le mong feela, 'me sekhahla sa ho nepahala ha ts'ebetso se fihlela maemo a 100%, ho netefatsa ka katleho phepelo ea boleng bo holimo ea li-busbar tsa sistimi ea motlakase.

3. Busbar ho Tlhahiso ea Liindasteri le Lisebelisoa tsa Elektroniki: Borokho bo Hokelang Matšoao le Matla

Masimong a boiketsetso ba indasteri le disebediswa tsa elektroniki, bese e bapala karolo ya "marangrang a methapo ya kutlo". Ha re nka mela ya tlhahiso ya boiketsetso ba indasteri e le mohlala, theknoloji ya fieldbus ke tshebediso e tlwaelehileng, jwalo ka PROFIBUS, CAN bus, jj. Di ka hokela di-sensor, di-actuator, balaodi le disebediswa tse ding marangrang ho fihlella phetiso ya data ya nako ya sebele le taolo e hokahantsweng ya disebediswa, e ntlafatsang haholo bokgoni ba tlhahiso le boemo ba boiketsetso. Masimong a khomphutha, bese ya sistimi hodima motherboard e ikarabella bakeng sa ho hokela CPU, memori, karete ya ditshwantsho, hard disk le dikarolo tse ding tsa bohlokwa. Bese ya data e fetisa tlhahisoleseding ya data, bese ya aterese e totobatsa sebaka sa polokelo ya data, mme bese ya taolo e hokahanya mesebetsi ya karolo ka nngwe ho netefatsa tshebetso e sebetsang hantle ya sistimi ya khomphutha.

Lisebelisoa tsa ho sebetsana le libese tsa Khamphani ea Gaoji li sebelisoa haholo indastering ea tlhahiso ea indasteri le ea lisebelisoa tsa elektroniki. Mohlala,Mochini oa ho betla le ho kuta oa CNC busbare ka etsa lits'ebetso tse kang ho phunya, ho betla, ho seha likhutlo, ho seha, ho khabisa le ho phunya libareng tsa libese tse nang le botenya ba ≤ 15mm, bophara ba ≤ 200mm, le bolelele ba ≤ 6000mm. Ho nepahala ha sebaka sa masoba ke ±0.1mm, ho nepahala ha sebaka ke ±0.05mm, 'me ho nepahala ha sebaka se pheta-phetoang ke ±0.03mm. E fana ka likarolo tsa libese tse nepahetseng haholo bakeng sa tlhahiso ea lisebelisoa tsa indasteri le tlhahiso ea lisebelisoa tsa elektroniki, e thusang ho ntlafatsa bohlale ba indasteri.

Mochini oa ho betla le ho kuta oa CNC busbar

4. Boqapi ba Theknoloji ea Libese le Mekhoa ea Nakong e Tlang

Ka ntshetsopele e matla ya masimo a ntseng a hlaha a kang eneji e ntjha, digridi tse bohlale, le puisano ya 5G, theknoloji ya busbar le yona e ntse e ntlafala kamehla. Theknoloji ya busbar e tsamaisang motlakase o mongata ke tataiso e tshepisang haholo ya ntshetsopele. Disebediswa tsa ho tsamaisa motlakase o mongata ha di na kganyetso le e nyane mochesong wa tsona o bohlokwa, di nolofalletsa phetiso ya motlakase o sa lahleheng, di ntlafatsa haholo bokgoni ba phetiso ya motlakase le ho fokotsa tahlehelo ya eneji. Ka nako e ts'oanang, dibese di ntse di leba ho kopantsweng le ho fetolwa ha modularization, di kopanya dibese le di-circuit breaker, di-disconnector, di-transformer, jj., ho theha disebediswa tse nyane le tse bohlale tsa kabo, ho fokotsa sebaka sa mokatong, le ho ntlafatsa boiketlo le botshepehi ba tshebetso le tlhokomelo.

Khamphani ea Gaoji e 'nile ea lula e tsamaisana le mekhoa ea boqapi ba theknoloji libareng tsa libese, e ntse e eketsa matsete a eona a lipatlisiso le nts'etsopele khafetsa, ka matsete a selemo le selemo theknolojing a ikarabellang bakeng sa chelete e fetang 6% ea chelete ea eona ea thekiso. Ka Tšitoe 2024, k'hamphani e ile ea fumana tokelo ea molao ea "Mokhoa oa ho fepa o fetolang bakeng sa mochini o kobehang oa libareng tsa libese tsa CNC o iketsang ka botlalo". Mokhoa ona o kopanya mesebetsi ea ho fepa le ho fetola, o kopantsoe le theknoloji e tsoetseng pele ea sensor, o ka beha leihlo boemo ba sehlahisoa ka nako ea sebele 'me oa fetola ka bohona, oa ntlafatsa katleho ea tlhahiso le ho nepahala ha ts'ebetso, oa fihlela litlhoko tsa ho kobeha libareng tsa libese tse bōpehileng joaloka tse rarahaneng, le ho kenya tšusumetso e ncha nts'etsopele ea theknoloji ea ts'ebetso ea libareng.

Leha busbar e ka bonahala e tloaelehile, e bapala karolo e ke keng ea nkeloa sebaka le ea bohlokoa phepelong ea matla le tlhahiso ea indasteri ea sechaba sa sejoale-joale. Ka lipatente tse mashome a tšeletseng tse ikemetseng tsa lipatlisiso le nts'etsopele, karolo ea 'maraka e fetang 70% Chaena, le katleho e ikhethang ea ho romela lihlahisoa linaheng le libakeng tse fetang leshome le metso e' meli lefatšeng ka bophara, Khamphani ea Gaoji e fetohile matla a bohlokoa a khannang tsoelo-pele le katoloso ea ts'ebeliso ea theknoloji ea busbar. Nakong e tlang, Gaoji e tla tsoela pele ho tsepamisa maikutlo libakeng tse kang ts'ebetso e bohlale le li-workshop tse se nang batho, e fana ka lisebelisoa tsa indasteri tse bohlale haholoanyane, tse loketseng le tse ntle bakeng sa liindasteri tse fapaneng. Hammoho le busbar, e tla ba mokhanni ea matla oa phetoho ea matla le phetoho e bohlale ea lekala la indasteri.

Nako ea poso: Phuptjane-19-2025